TOOL DESIGN

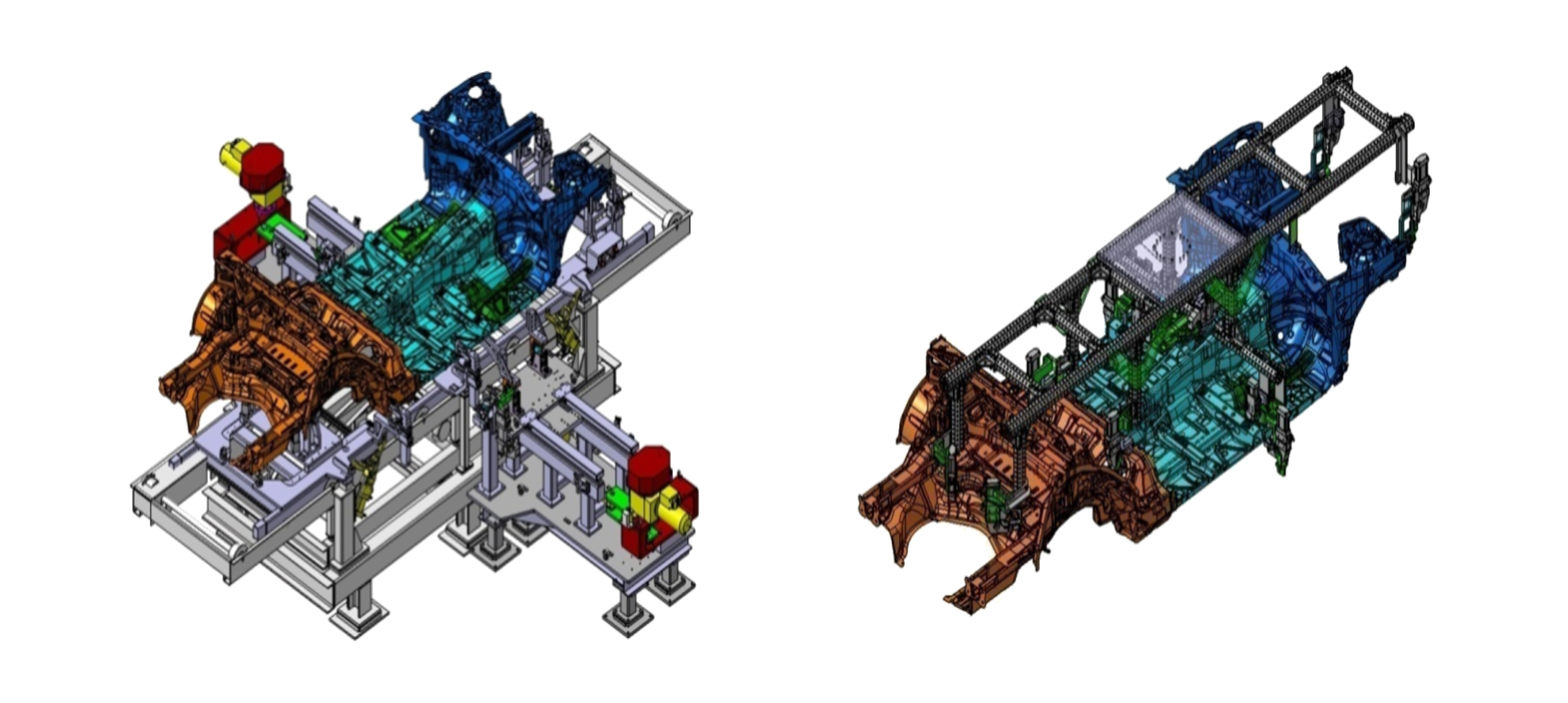

Each Tool is a special one & and unique one. And that’s why we design each Tool for its own unique function. We see what is the process on this tool and then design an optimum way to hold the body panels, so that the right Geometry Tolerances of the assembly are achieved.

Not just for its own function, but each Tool also has to be evaluated for, how it fits with the overall process of the Zone. Special consideration is put to seemingly simple but very important points,

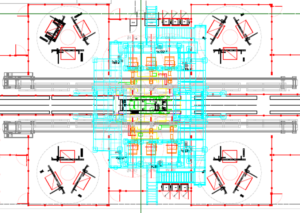

- where and how it is mounted

- what are the clearances from nearby Tools and other equiments

- what happens when the clamps open and close

- who is working on it a Robot or a Man, from which direction and so on.

Many a times, the design process starts with the buy Clamp Plan buy off, either with our internal Process & Layout engineers or with the Customer. Then unit by unit the Tool is designed. While the Key focus is on functionality of each unit, special importance is also given to

- manufacturability of each make part

- how easily they can be assembled

- how easy would it be for the Quality person to certify

- the completeness of information for right ordering for the Purchase parts.

All our Tool designs are checked in 3D stage by a “Senior Person Review” and in 2D stage by a Quality Checking team before the drawings are released for manufacturing.

FEATURED COMPETENCIES

Closures

Cladding, Manual & Automatic

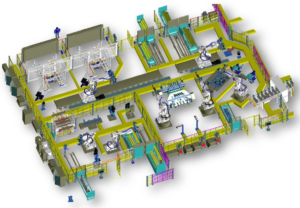

Framing Line

Framing Line

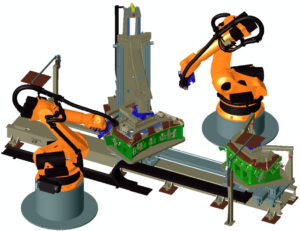

Body Side Grippers

Turn Tables, Trunions

Body Side Lines

Sub Assemblies

Underbody Line

Sub Assemblies

Hemming

Table Top, Hybrid Hemming

Roller Hemming

Prototype Tools

Spot welding, Clinching

Spot welding, Clinching

Laser welding

Arc welding

Robotics Grippers

Conveyors

LCAs

SOFTWARE COMPETENCIES

![]() Catia v5

Catia v5

![]()

Siemens NX

RELATED COMPETENCIES