FINAL ASSEMBLY

Putting together all our experience of Manufacturing Planning and Product Development, we are able to bring the most optimal solution for the Final Assembly area.

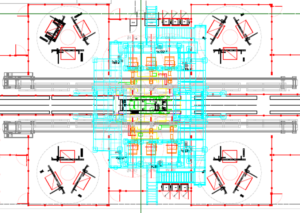

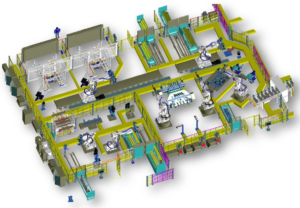

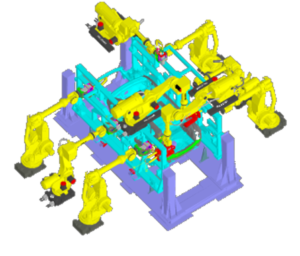

From our Manufacturing Planning side, our Simulation capabilities help us to Virtually Build the complete Final Assembly line in 3D. This way, we can not only clearly visualize but also analyse the Assembly Line, for Cycle Time, Through put, Layout placements, etc.

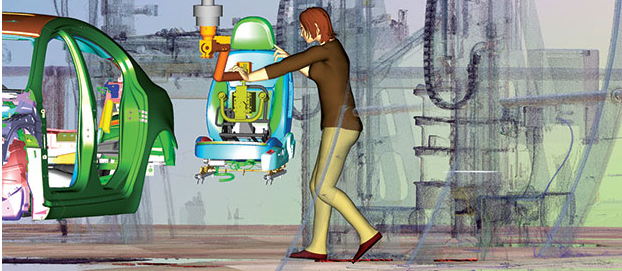

One of the most critical topics here is, of course, Operator‘s Health & Safety. For this we are running various Man, Tool & Job assessments, to check both Operator Ergonomics as well as, Operator Fatigue.

From our Product Development side, our 3D Tolerance Variation Analysis helps us predict the Gap & Flush behaviour of large assemblies. Then we can go backwards and recommend the optimum Locator Plan.

Also, we can use our experience on Vis Mock-up to understand the clearances either for fitment of large assemblies with each other. And also for the operator & nut-runner‘s access, in tight difficult corners.

All this we can further support by providing right documentations around all these topics. Small but not insignificant are the Specifications for Fasteners and also the torque requirements for their optimum tightening levels.

FEATURED COMPETENCIES

Virtual Build

New Product Introduction

Assembly sequence

Digital Pre-Assembly

Digital Pre-Assembly

Measure & Confirm clearances

Static & Dynamic Study

Plant Layout

Plant Layout

3D & 2 D

Cycle Time Calculation

Throughput Analysis &

Optimization

3D Tolerance Analysis

Dimensional Variational Analysis

Locator plan optimization

Man, Tool & Job assessment

Man, Tool & Job assessment

Fatigue assessment

Lifting & Lowering assessment

Fasteners (Bolts & Nuts) Specifications,

Torque values & Gun definition

SOFTWARE COMPETENCIES

AutoCAD

![]()

Microstation

![]()

Catia v5

Siemens NX

![]()

Vis Mock-up

Vis VSA Factory CAD,

PD, PS, Robcad

![]()

3DCS

RELATED COMPETENCIES