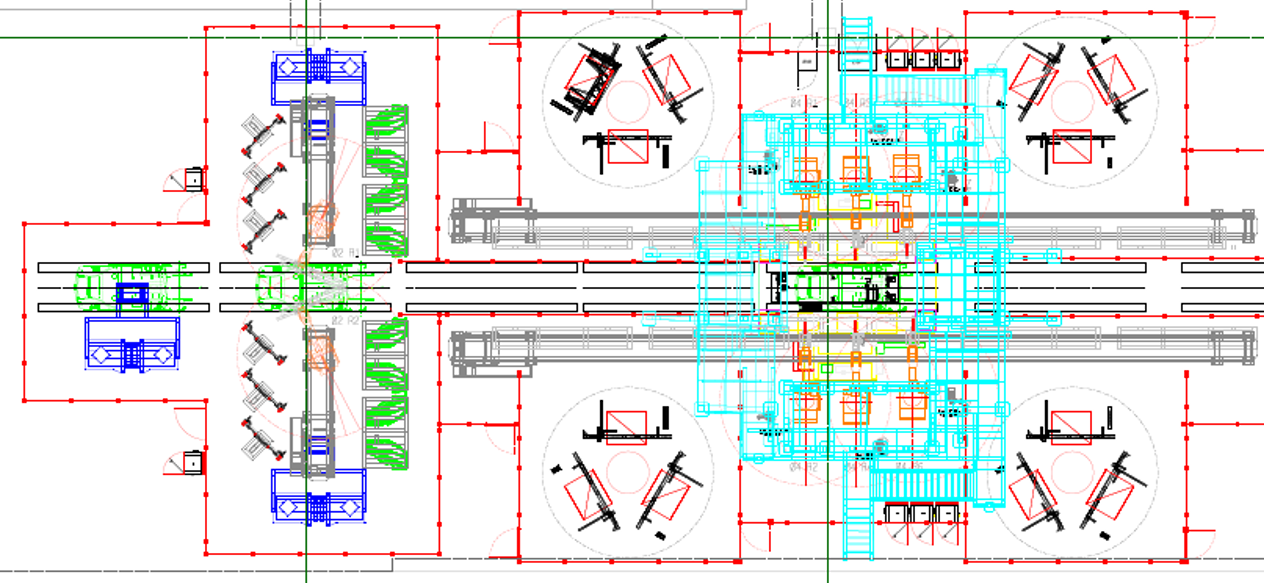

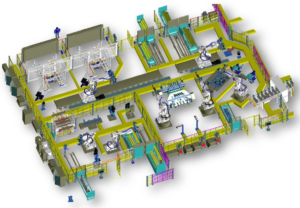

PROCESS & LAYOUT

Each process is about meeting a Production Target. Of course, there are other constraints, e.g. level of Automation, available plant space, existing equipments and their re-use, ongoing production of other models and most importantly, available budget (capital expenditure).

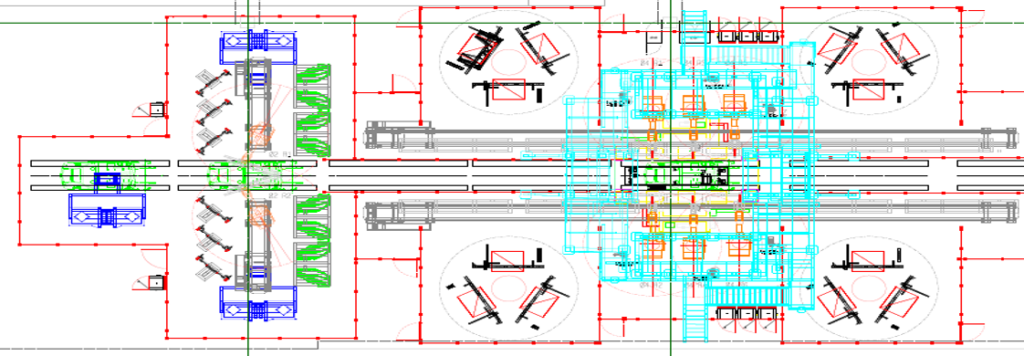

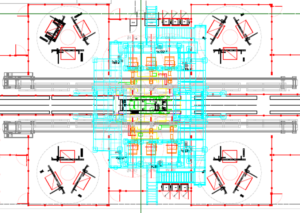

At a block level, we have to give special consideration to the high level material flow, possible bottle necks, conveyors, racks and buffers, logistics, ease of maintenance, personell movement, etc.

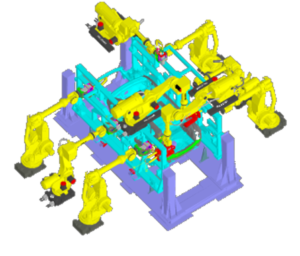

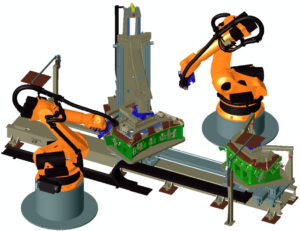

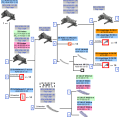

Step by step the next level of detail is worked out. At the Zone level; product geometry and the Joining technologies, largely drive the build sequence and also the material flow in the Zone.

At the Cell level; available Cycle time and Panel orientation define the station wise break down of processes, the layout and positioning of equipments & Robots, interaction with the Operator.

Special attention is paid to the problems that are lying hidden in the detail of the things; normally, where these conditions occur together,

- Last minute changes in the Joining data, Panel geometry, build sequence, etc.

- Not enough Cycle time available

- Panel orientation is wrong / sub-optimal (leading to bulkier equipments, Robots with higher payloads, safety issues, ergonomic issues, etc.)

- Existing equipments do not allow any more space

In a Greenfield project, we try to find optimum solution by redrawing the process, which can be quite involved, but achievable when right thinking is put in these simple steps,

- Revising the Build sequence

- Re-distributing the Spots

- Re-doing the layout

etc.

However for an integration project, such a major change in the process is simply not possible, because it is way too costly. There we have to think harder and find highly innovative and pointed solutions, e.g.

- Re-distribute only few spots

- Replace 1 or 2 equipments / Robots

- Add a special purpose operation, directly in the existing tool

- Try to optimise Robot programs

etc.

In the end, a working process should also be a cost effective and functionally optimised process.

FEATURED COMPETENCIES

Plant Layout

3D & 2D

Cycle Time Calculation

Cycle Time Calculation

Technical Availability

Utilization for Equipment / Zone

Throughput Analysis &

Optimization

Discrete Event Simulation

Method time Management

Ergonomic Study & Simulation

using Manual charts & Software

Joining Sequence

Station wise break down

Weld Plan, Glue Plan

Clamp Plan

Clamp Plan

Panel Orientation

Material Flow

Process FMEA

Process FMEA

for Equipments or

Zone

SOFTWARE COMPETENCIES

AutoCAD

![]()

Microstation

Catia v5

Siemens NX

Process Designer

RELATED COMPETENCIES